Call us now:

The manufacturing process of automotive rubber products is a sophisticated and precise operation that ensures the production of high-quality components, including sealing plugs, sealing rings, and protective covers. Below is a detailed description of the key stages involved in the production process, accompanied by a diagram illustrating the workflow.

Manufacturing Process

- Raw Material Selection and Preparation

- Material Selection: The process begins with the careful selection of raw materials, typically natural or synthetic rubber, along with additives like fillers, plasticizers, and curing agents. The choice of material depends on the specific requirements of the automotive component, such as resistance to heat, oil, and environmental stress.

- Mixing: The selected materials are then mixed in a Banbury mixer or on a two-roll mill. This step ensures a homogeneous blend, with the additives evenly dispersed throughout the rubber compound.

- Molding

- Pre-forming: The mixed rubber compound is pre-formed into specific shapes, such as sheets or strips, to facilitate the molding process.

- Molding Methods: Depending on the product, different molding techniques are used, including compression molding, transfer molding, and injection molding. The pre-formed rubber is placed into a mold cavity, which is then closed and subjected to heat and pressure.

- Curing (Vulcanization)

- Curing Process: The molded rubber components undergo vulcanization, a chemical process that involves heating the rubber with sulfur or other curatives. This step cross-links the polymer chains, enhancing the material’s elasticity, strength, and thermal stability.

- Quality Control: Throughout the curing process, parameters such as temperature, pressure, and time are meticulously controlled to ensure optimal product properties.

- Trimming and Finishing

- Trimming: After curing, excess material (flash) is trimmed off the molded components to achieve precise dimensions and a clean finish.

- Surface Treatment: The products may undergo additional surface treatments, such as coating or texturing, to improve their performance and durability.

- Inspection and Testing

- Visual Inspection: Each component is visually inspected for defects or inconsistencies.

- Performance Testing: Rigorous testing is conducted to ensure that the rubber products meet the required specifications. This includes tests for tensile strength, elongation, hardness, and resistance to environmental factors.

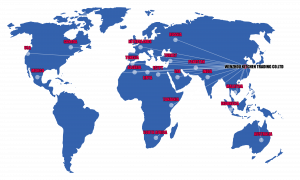

- Packaging and Distribution

- Packaging: The final products are carefully packaged to protect them from damage during transit.

- Distribution: The packaged products are then distributed to automotive manufacturers and suppliers worldwide.

Process Flow Diagram

Below is a detailed diagram illustrating the automotive rubber products manufacturing process:

+-----------------------------+

| Raw Material Selection |

| and Preparation |

+-----------------------------+

|

v

+-----------------------------+

| Mixing |

+-----------------------------+

|

v

+-----------------------------+

| Pre-forming |

+-----------------------------+

|

v

+-----------------------------+

| Molding |

| (Compression, Transfer, |

| or Injection) |

+-----------------------------+

|

v

+-----------------------------+

| Curing (Vulcanization) |

+-----------------------------+

|

v

+-----------------------------+

| Trimming and Finishing |

+-----------------------------+

|

v

+-----------------------------+

| Inspection and Testing |

+-----------------------------+

|

v

+-----------------------------+

| Packaging and Distribution |

+-----------------------------+

Analysis

The precision and quality control involved in the manufacturing process of automotive rubber products ensure their reliability and performance in various applications. By using advanced molding and curing techniques, manufacturers can produce components that meet the stringent demands of the automotive industry. Furthermore, continuous innovation in material science and processing technology is driving improvements in the durability, functionality, and environmental sustainability of these products.

By understanding and implementing this detailed manufacturing process, Wenzhou Chushidun Trading Co., Ltd. can maintain its competitive edge and continue to deliver top-notch automotive rubber components to its clients worldwide.us molestie.